VT30

Category:

Product Description

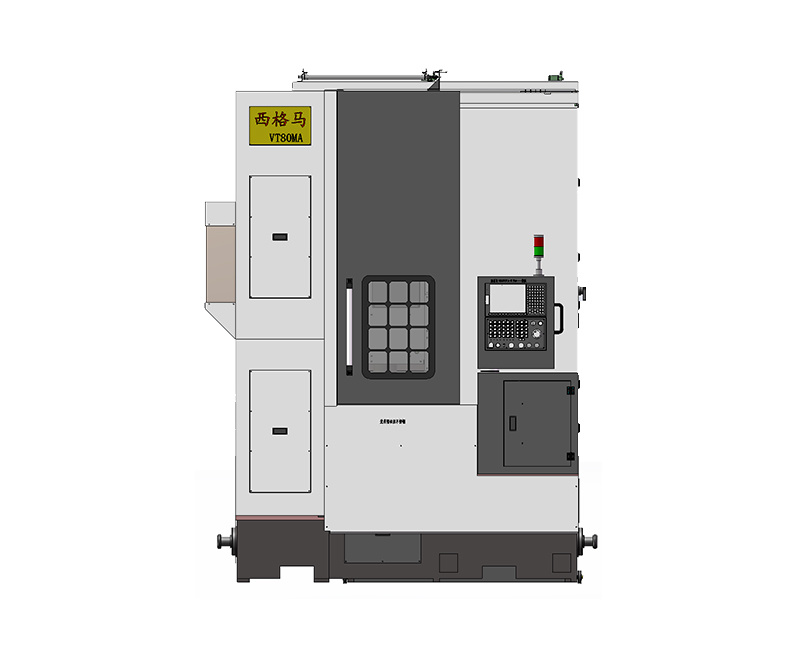

VT30 PLUS CNC lathe is a two-coordinate two-axis linkage, semi-closed-loop control vertical CNC lathe. The main machine adopts the whole bed, and the whole Z-backward column structure is arranged. Linear rolling guide, ball screw drive, good dynamic characteristics, high precision, strong rigidity. The protection adopts fully enclosed protection, left open external sliding door, independent chip collection water tank, good chip removal performance. The control system adopts Mitsubishi E80 (or FANUC) control system and AC longitudinal and transverse servo motors.

machine tool processing objects and uses:

1) It can process short shaft parts and disc parts with a diameter Ф 500mm and a height below 480mm; The maximum rotation diameter of the saddle Ф 630mm.

2) the processing geometry is complex, the size is various, the precision requirement is high short shaft (or disc) parts.

3) processing cylindrical surface, conical surface, step surface, spherical surface and other kinds of rotary surface parts.

4) processing all kinds of male and imperial internal and external threads.

5) In addition to turning, it can also be used for drilling, expanding, reaming, rolling and boring.

2. Features of machine tool:

1) machine, electricity, hydraulic integration and modular design, reasonable layout, compact structure, pleasant operation, easy maintenance.

2) the use of preload linear rolling guide and ball screw, with high speed, high precision processing characteristics.

3) The spindle adopts imported bearings (NSK, Japan) and is coated with German KLUBER high-grade grease, with high precision, strong rigidity and long life.

4) The horizontal hydraulic servo turret, which relies on high precision and large diameter tooth disc centering, has the functions of no lifting, high precision, fast indexing speed and bidirectional nearby knife selection. And less failure, long life. (Option: the third servo feed axis of the double brake surface of the processing brake disc).

5) Automatic centralized lubrication device, sufficient and reliable lubrication, automatic control of lubrication cycle.

6) The Japanese Mitsubishi E80 (or FANUC) high-performance AC servo motor and driver, fast moving speed, high positioning accuracy, stable and reliable performance.

7) 18.5Kw/26Kw built-in special electric spindle and high-performance spindle drive are adopted, with large variable speed range, stepless variable speed, constant linear speed cutting and directional parking can be realized.

8) 12 inches, 15 inches (choose one) hydraulic power chuck, convenient and reliable loading and unloading, reduce the labor intensity of the operator.

9) The cooling system adopts high-lift, large-flow, high-power water pump, and the water in the cutter head is cooled, which can obtain strong cutting cleaning and cooling effect.

10) The chip collection box is completely separated from the fuselage to avoid deformation of the fuselage due to chip heat. Rear automatic chip conveyor, iron chips are automatically discharged out of the machine (option).

11) Oil and water are separated to prevent lubricating oil from polluting the cutting fluid.

12) fully enclosed protection design, no water leakage, no oil leakage, beautiful appearance, pleasant operation.

| Operation ability | |

| Maximum turning diameter on the bed | Ф 630 ㎜ |

| Max turning diameter | Ф 500 ㎜ |

| Maximum drilling diameter | Ф 32mm |

| Maximum turning height | 480 ㎜ |

| Maximum travel | |

| X direction | 260mm |

| Z direction | 480mm |

| Headstock | |

| Spindle speed range | 50-2500r/min |

| Basic spindle speed | 200r/min |

| Electric spindle power | 18.5/26KW |

| Maximum output torque of spindle | 140Nm |

| Spindle head type | Short cone; A2-8 mm |

| Dimension of front shaft diameter of main shaft | Ф 120 ㎜ |

| Fast forward speed | |

| X direction | 20m/min |

| Z direction | 20m/min |

| Knife Tower | |

| Drive mode | hydraulic servo |

| Type of turret | Horizontal |

| Number of knives | 8-bit;(12-bit) option |

| Single station indexing time | 0.6 seconds |

| Square dimension of circular cutter | 25mm × 25mm (choose one) |

| Tool holder boring tool holder quantity | 4 |

| Number of tool holder end face holder | 1 |

| Diameter of boring bar | Ф 40mm |

| Chuck | |

| Zhongshi hydraulic power chuck | 10 inches/12 inches |

| External dimensions of machine tool | |

| Dimensions | 1560mm × 2370mm × 2660mm |

| Machine weight | |

| Net weight | 4000 ㎏ (excluding chip conveyor) |

| gross weight | 4500 ㎏ (including chip conveyor) |

Key words:

Related Products

Welcome your message consultation