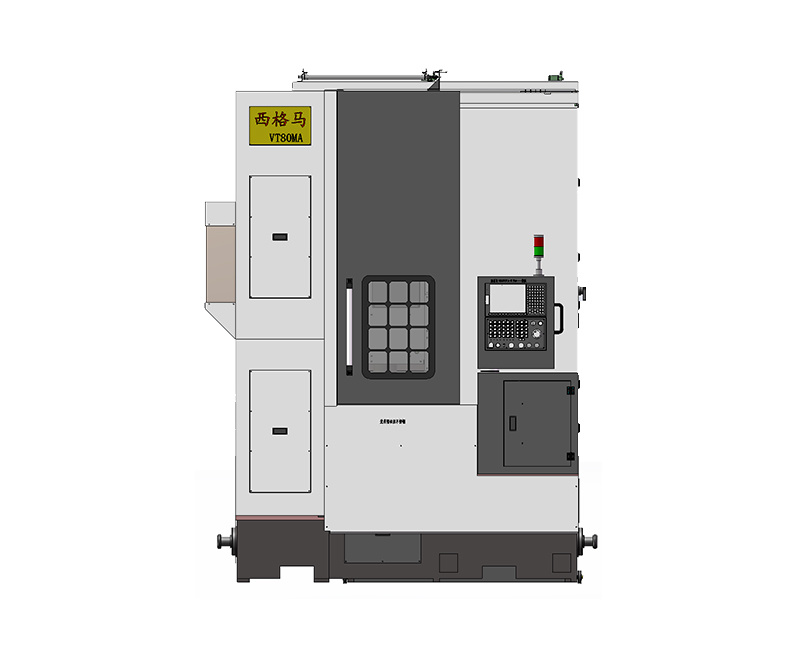

QT200MSY

Category:

Product Description

1. Spindle:The spindle adopts a high-power, high-torque built-in electric spindle structure, and the spindle is equipped with a cooling device. This structure not only ensures the high rigidity and high speed of the spindle, but also ensures that the spindle temperature rise is low during high-speed operation, and the spindle is thermally balanced before and after, and the thermal deformation is small.

2. Knife Tower:The 12-station hydraulic servo power turret is adopted, the servo motor is used for indexing, the triple mouse tooth plate structure is adopted, the cutter plate has no lifting action, and has the characteristics of high positioning accuracy and strong rigidity.

3. Hydraulic system:Equipped with an independent hydraulic system to ensure reliable clamping of the chuck and accurate rotation of the turret.

4. Lubrication system:The guide rail and ball screw pair are all lubricated by centralized automatic thin oil, and each node is equipped with a quantitative distributor to inject oil to each lubricating part regularly and quantitatively to ensure uniform lubrication of each sliding surface, effectively reducing friction resistance and improving movement accuracy, To ensure the service life of the ball screw pair and the guide rail.

5. Cooling system:Equipped with large flow cooling pump and large capacity water tank, fully guarantee the circulation cooling in the cutting process.

6. Machine tool protection:The machine adopts the sheet metal full protection and automatic door in accordance with the safety standards, which not only prevents the coolant from splashing, but also ensures the safety and convenience of operation. Each guide rail of the machine tool has a protective cover to prevent chips and coolant from entering the inside of the machine tool, so that the guide rail and screw are free from pollution and corrosion. With automated pneumatic sunroof sliding door.

Main specifications and parameters

| Maximum travel | |

| X Axis | 215mm |

| Y axis | 100mm(±50) |

| Z-axis | 605mm |

| W-axis | 585mm |

| Processing range (Max) | |

| Maximum machining diameter | 320mm |

| Maximum swing diameter | 695mm |

| 1st spindle | |

| Spindle power | 22Kw |

| Spindle through hole diameter | Φ67mm |

| Spindle speed | 4000r/min |

| Chuck Interface | A2-6r/min |

| 2nd spindle | |

| Spindle power | 11Kw |

| Spindle through hole diameter | Φ53mm |

| Spindle speed | 6000rpm |

| Chuck Interface | A2-5 |

| Tail | |

| Taper hole taper | 4#/5# |

| Diameter of tailstock sleeve | 75mm |

| Knife Tower | |

| Tool capacity | 12pcs |

| Tool indexing time | 0.23sec/bit |

| Tool body size | 25mm × 25mm |

| Maximum boring tool diameter | Φ40KW |

| Knife holder | 2 outer diameter tool holders and 4 inner hole tool holders |

| Power knife holder | BMT55-ER32-0 ° 1 |

| Power knife holder | BMT55-ER32-90 ° 1 |

| milling spindle | |

| Maximum speed of milling spindle | 4000rpm |

| Output power (continuous/40) | 3.7KW/5.5KW |

| Maximum end mill diameter | Φ20mm |

| Maximum diameter of drilling tool | Φ20mm |

| Max. diameter of tap | M20mm × 2.5mm |

| Hydraulic station motor | |

| Motor | 1.5kw |

| Fast moving speed | |

| Fast moving speed: X/Y/Z | 1930m/min/10m/min/30m/min. |

| Cooling system | |

| Water tank volume | 185L |

| net weight of machine tool | |

| net weight of machine tool | 5000kg |

Key words:

Related Products

Welcome your message consultation