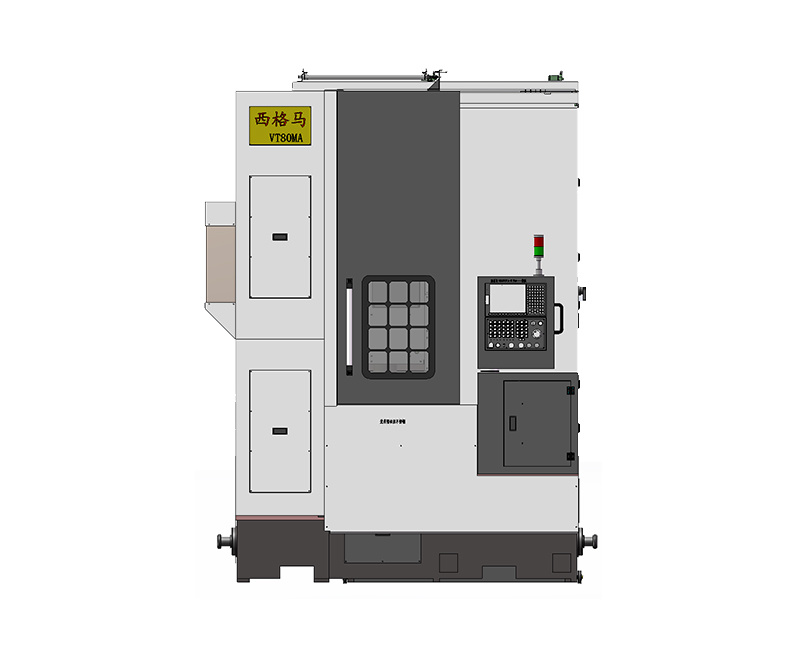

QT4060M CNC lathe is a two-coordinate continuous control CNC lathe. It adopts the reasonable layout of electromechanical hydraulic (or gas) integration, eight-station hydraulic servo turret and BT40 milling spindle, which has the advantages of simple structure, stable performance and reliable use. It is suitable for turning shaft and disc parts, as well as drilling and tapping of end faces of parts. It combines turning and milling together to complete one-time processing, especially for parts with complex shapes and high precision. With the perfect function of the control system, it can process internal and external cylinders, cones, arcs and various threads.

The overall box-type inclined bed of the main engine is arranged with a smooth saddle structure, which has the advantages of large operating space and smooth chip removal. The whole bed has good rigidity and strong anti-deformation ability. Both X and Z adopt high-precision load rolling guide rails and ball screws imported from Japan. The friction coefficient is small, the wear resistance is good, the accuracy of the machine tool is increased, the fast moving speed of the tool holder is improved, and the service life of the machine tool is prolonged.

This machine is the motor through the high-speed belt direct drive spindle, there is no intermediate gear transmission link, so smooth transmission, low noise. The front bearing of the main shaft adopts double row cylindrical roller bearings and two angular contact ball bearings, which bear radial force and axial force at the same time. The rear bearing adopts double row cylindrical roller bearings to bear radial force. This structure ensures the high rigidity and high speed of the main shaft, and ensures the low temperature rise of the main shaft during high-speed operation, the thermal balance before and after the main shaft, and the small thermal deformation.

Main specifications and parameters

| Maximum travel |

| X Axis |

250mm |

| Z-axis |

750mm |

| Processing range (Max) |

| Maximum processing length |

680mm |

| Maximum machining diameter |

470mm |

| Maximum swing diameter |

640mm |

| Spindle |

| Spindle diameter |

Φ92mm |

| Spindle speed |

50-1800r/min |

| Knife Tower |

| Number of tools |

8pcs |

| Maximum diameter of tool hole |

Φ40mm |

| Turning tool square knife |

25mmx25mm |

| milling spindle |

| Type |

Belt drive |

| Taper Hole Type |

BT40 |

| Maximum speed |

3000rpm |

| Motor power |

7.5KW |

| Motor torque |

48Nm |

| Reduction ratio |

1:01 |

| Tool magazine |

| Tool magazine type |

Disc type servo drive |

| Tool capacity |

9pcs |

| Tool change time (knife-knife) |

3sec |

| Tool change time (cutting-cutting) |

5sec |

| Max tool length |

200mm |

| Max tool diameter/adjacent without knife |

80mm/160mm |

| Max tool weight |

8Kg |

| Hydraulic station motor |

| Motor |

2.2kw |

| Fast moving speed |

| Fast moving speed: X /Z |

24m/40min |

| Main motor power |

| Motor power |

18.5kw |

| Feed motor |

| X |

2.3kw |

| Z |

2.9kw |

| Overall dimensions of machine tool (W×D×H) |

| Dimensions |

2600mm × 2150mm × 2200mm |