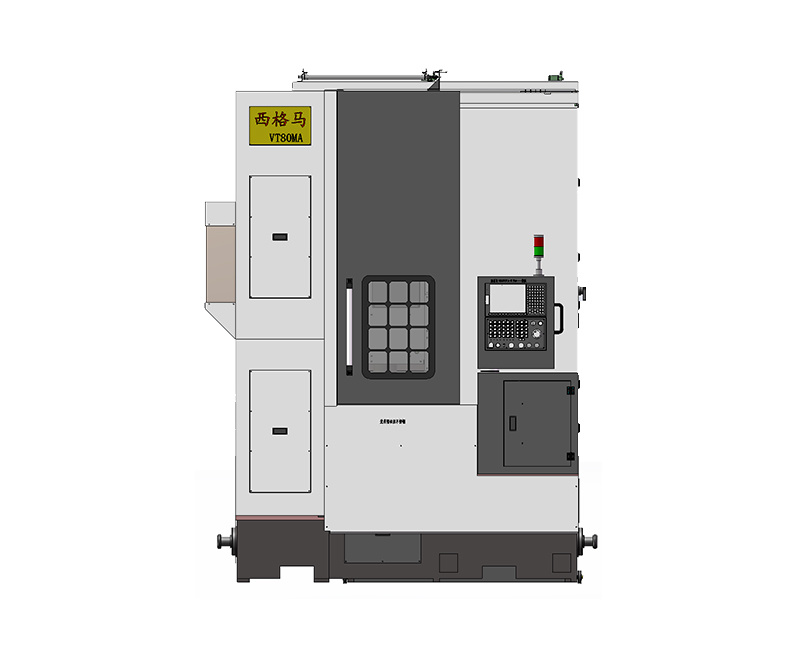

CT2550[3250] A/B

Category:

Product Description

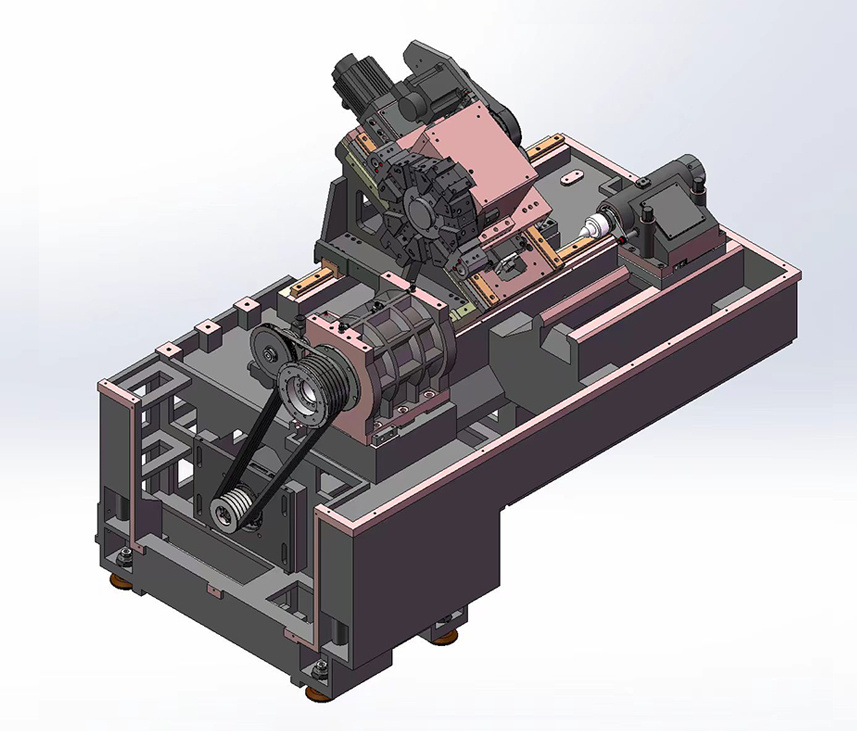

1. Host structure |

2. Spindle system |

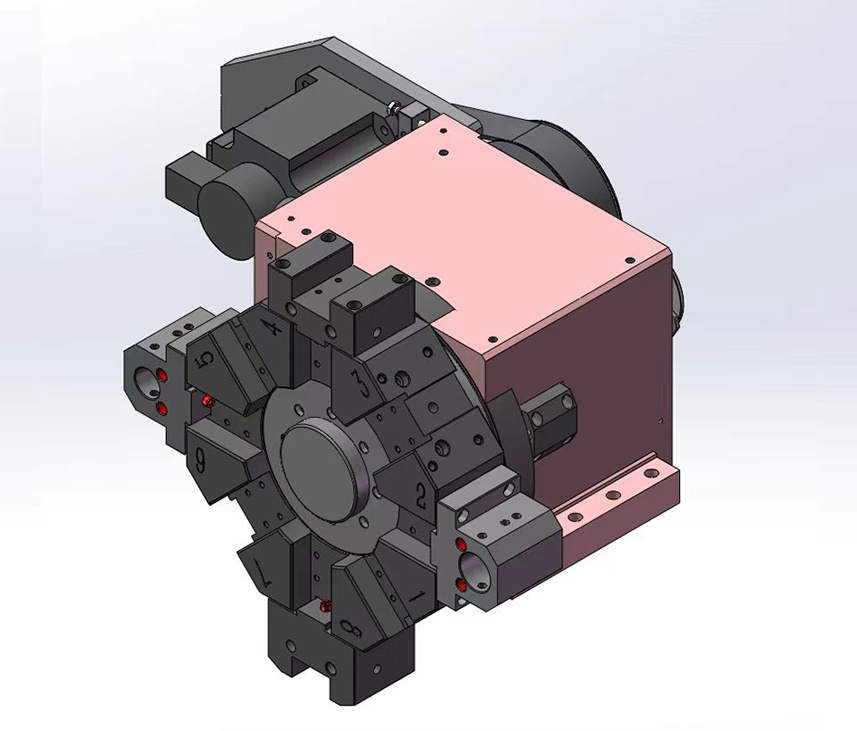

3. Knife Tower |

1. Host structure: The whole box-type bed is arranged with 30 ° inclined sliding saddle. Bed, spindle box, sliding saddle, skateboard and other large parts are made of high-strength cast iron materials, the use of three-dimensional computer software to optimize the design to ensure the strength of the machine and dynamic and static stiffness. Through the perfect multi-sequence aging treatment process control to eliminate the residual stress of the casting, to ensure that the whole machine has sufficient stability and precision retention.

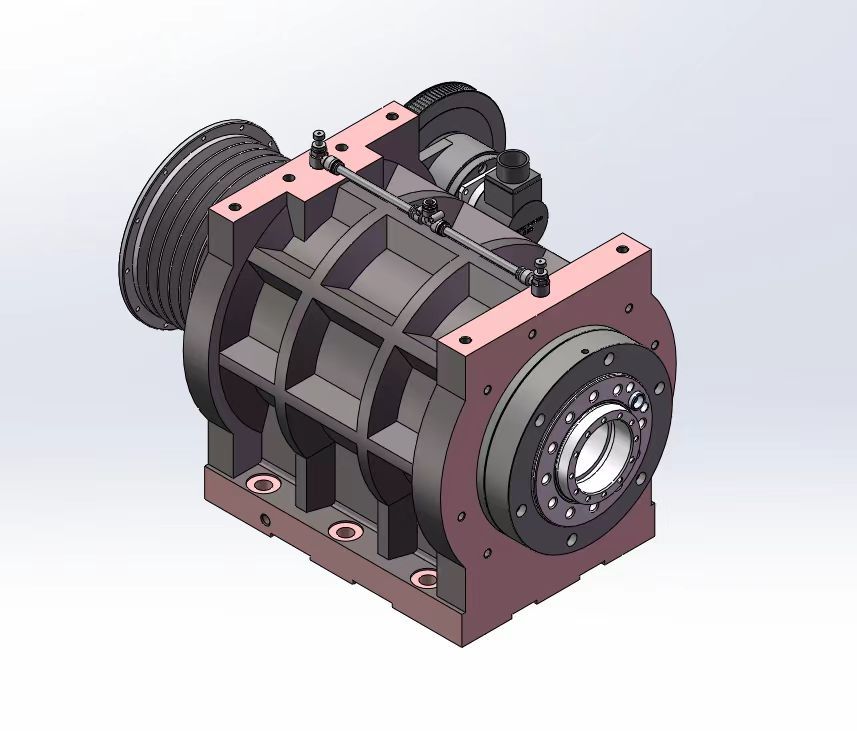

2. Spindle system: Large span design structure and equipped with high-precision spindle bearings, auxiliary airtight protection, to ensure the accuracy of the spindle, service life and reliability.

3. Knife Tower: Relying on the hydraulic servo turret Ф 200mm large diameter and high-precision tooth disc centering, it has the advantages of high precision, fast rotation speed, few failures and long life.

Main technical parameters of machine tool

| Processing capacity | |

| Chuck size | Standard: 8inch |

| Maximum Spin Diameter | Ф 500 ㎜ |

| Standard turning diameter | Ф 260 ㎜ |

| Max turning diameter | Ф 360 ㎜ |

| Standard turning length 8 inch chuck | 510 ㎜ |

| Standard turning length 10 inch chuck | 490 ㎜ |

| Maximum load (including chuck) | 200Kg |

| Headstock | |

| Spindle speed range | 50r/min-3500r/min: |

| Spindle end Model | A2-6 |

| Main motor power (rated/continuous) | 11Kw-15Kw |

| Torque (rated/continuous) | 127Nm/173Nm |

| Dimension of front shaft diameter of main shaft | Ф 110 ㎜ |

| Spindle through diameter | Ф 76 ㎜ |

| Bar diameter | Standard: Ф 51mm |

| Tailstock (option) | |

| Maximum stroke of tailstock sleeve | 90 |

| Diameter of tailstock sleeve | F75 |

| Tailstock sleeve taper | 4# |

| feed axis | |

| Travel X direction | 200 ㎜ |

| Travel Z direction | 555 ㎜ |

| Fast forward speed X direction | 20m/min |

| Fast forward speed Z direction | 20m/min |

| Knife Tower | |

| Drive mode | hydraulic servo |

| Number of work | Standard: 8-bit/Option: 1-bit/12-bit |

| Single station indexing time | 0.2 seconds |

| Cutter size square cutter bar | □ 25mm |

| Tool size Boring bar | Ф 32mm |

| Number of boring tool holders | 4 |

| Number of end face holder | 1 |

| Overall dimensions of machine tool (length×width×height) | |

| Dimensions | 1950mm × 1750mm × 1730mm |

| net weight of machine tool | |

| net weight of machine tool | 3500kg |

Key words:

Related Products

Welcome your message consultation

![CT2550[3250] A/B CT2550[3250] A/B](https://omo-oss-image.thefastimg.com/portal-saas/new2023111119050210158/cms/image/4a8de9a5-c7d0-4faf-8e51-5baf6b5f584f.jpg)

![CT2550[3250] A/B CT2550[3250] A/B](https://omo-oss-image.thefastimg.com/portal-saas/new2023111119050210158/cms/image/cb5c9f06-5c43-4748-a8b3-935d4e395433.jpg)

![CT2550[3250] A/B CT2550[3250] A/B](https://omo-oss-image.thefastimg.com/portal-saas/new2023111119050210158/cms/image/0fd23b5e-f8f0-4561-bf79-183f7d891063.jpg)