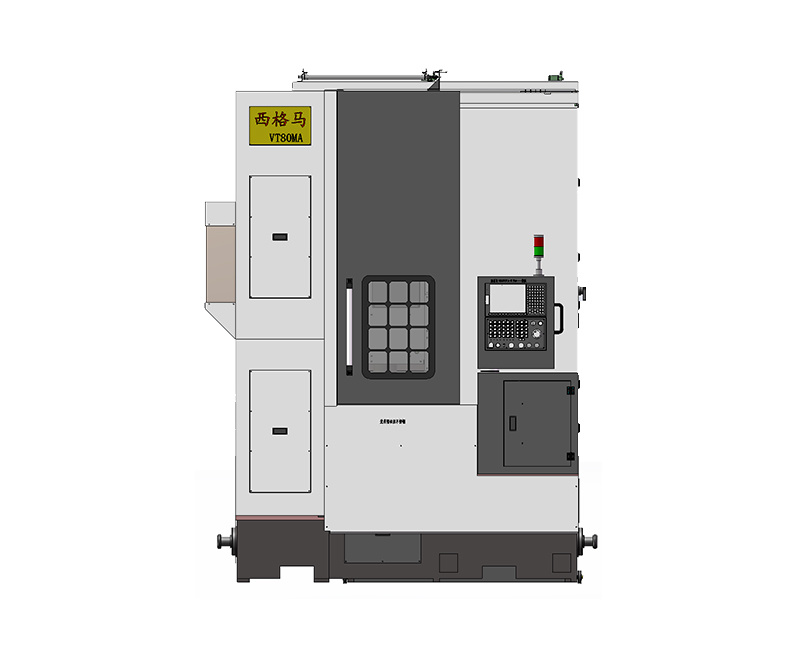

VT80MA adopts two-coordinate two-axis linkage, semi-closed loop control vertical CNC lathe. The host adopts the whole bed moving column structure design, linear rolling guide support, ball screw drive. The protection adopts a fully enclosed protective cover, a left-open external sliding door, an independent chip collection water tank, and a twelve-station hydraulic servo power turret. It has the advantages of simple structure, stable performance, and reliable use.

1. Spindle: The spindle adopts high rigidity mechanical spindle, equipped with large torque main motor

2. Milling spindle: BT40 belt connection, center water outlet

3. turret: 12-station hydraulic servo power turret, servo motor indexing, built-in rat tooth plate, with high positioning accuracy, strong rigidity and so on.

4. Hydraulic system: Equipped with an independent hydraulic system to ensure reliable clamping of the chuck and accurate indexing of the turret.

5. Lubrication system: The guide rail and ball screw pair are all lubricated by centralized automatic thin oil. Each node is equipped with a quantitative distributor, and oil is injected into each lubricating part regularly and quantitatively to ensure uniform lubrication of each sliding surface and effectively reduce friction resistance, Improve the movement accuracy and ensure the service life of the ball screw pair and the guide rail.

6. Cooling system: equipped with large flow cooling pump and large capacity water tank, fully guarantee the circulating cooling in the cutting process.

7. Machine tool protection: The machine tool adopts full protection of sheet metal and automatic doors that meet safety standards, which not only prevents coolant from splashing, but also ensures safe and humane operation. Each guide rail of the machine tool has a protective cover to prevent chips and coolant from entering the inside of the machine tool, so that the guide rail and screw are free from pollution and corrosion. With automated pneumatic sunroof sliding door (option).

| Maximum travel |

| X Axis |

550mm |

| Z-axis |

860mm |

| Processing range (Max) |

| Maximum machining diameter |

850mm |

| Maximum swing diameter |

1100mm |

| Spindle |

| Spindle power |

37Kw |

| Front shaft diameter |

Φ240mm |

| Spindle through hole diameter |

Φ100mm |

| Spindle speed |

1000r/min |

| Chuck Interface |

A2-15 |

| Knife Tower |

| Tool capacity |

12pcs |

| Tool indexing time |

0.45sec/bit |

| Tool body size |

32mm × 32mm |

| Maximum boring tool diameter |

Φ60KW |

| milling spindle |

| Type |

Belt drive |

| Taper Hole Type |

BT40 |

| Maximum speed |

8000rpm |

| Motor power |

7.5KW/11KW |

| Motor torque |

48Nm |

| Reduction ratio |

1:01 |

| Tool magazine |

| Tool magazine type |

disc type |

| Tool capacity |

16pcs |

| Tool change time (knife-knife) |

2sec |

| Max tool length |

300mm |

| Max tool diameter/adjacent without knife |

80/160mm |

| Max tool weight |

8Kg |

| Hydraulic station |

| Motor |

2.2kw |

| Fast moving speed |

| Fast moving speed: X/Z |

20/20m/min |

| Cooling system |

| Water tank volume |

200L |

| Overall dimensions of machine tool (W×D×H) |

| Dimensions |

2800mm × 3050mm × 3600mm |

| net weight of machine tool |

| Net weight |

10000kg |