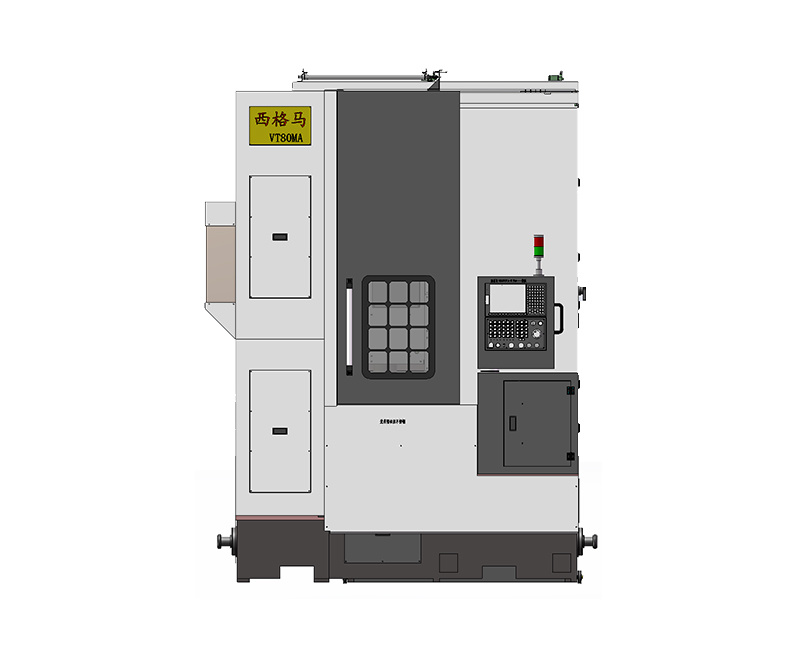

CT2530 A/B

Category:

Product Description

1. Host structure: The whole box-type bed is arranged with 30 ° inclined sliding saddle. Bed, spindle box, sliding saddle, skateboard and other large parts are made of high-strength cast iron materials, the use of three-dimensional computer software to optimize the design to ensure the strength of the machine and dynamic and static stiffness. Through the perfect multi-sequence aging treatment process control to eliminate the residual stress of the casting, to ensure that the whole machine has sufficient stability and precision retention.

2. Feeding system: The guide rail pair adopts imported rolling linear guide rail, which has low dynamic and static friction, high positioning accuracy and long life. The ball screw adopts imported high-precision ball screw, with accurate positioning and high transmission accuracy.

3. Spindle system: Large span design structure and equipped with high-precision spindle bearings, auxiliary airtight protection, to ensure the accuracy of the spindle, service life and reliability.

4. Knife Tower: Relying on the hydraulic servo turret Ф 200mm large diameter and high-precision tooth disc centering, it has the advantages of high precision, fast rotation speed, few failures and long life.

5. Hydraulic system: Equipped with an independent hydraulic system to ensure reliable clamping of the chuck and accurate rotation of the turret.

6. Lubrication system: The guide rail and ball screw pair are all lubricated with centralized automatic thin oil. Each node is equipped with a quantitative distributor. Oil is injected into each lubricating part regularly and quantitatively to ensure uniform lubrication of each sliding surface, effectively reducing friction resistance and improving movement. Accuracy ensures the service life of the ball screw pair and the guide rail.

7. Cooling system: Equipped with large flow cooling pump and large capacity water tank, fully guarantee the circulating cooling in the cutting process.

8. Machine Tool Protection: The machine adopts full protection of sheet metal and automatic doors in accordance with safety standards, which not only prevents coolant from splashing, but also ensures safe and humane operation. Each guide rail of the machine tool has a protective cover to prevent chips and coolant from entering the inside of the machine tool, so that the guide rail and screw are free from pollution and corrosion. With automated pneumatic sunroof sliding door. (Option)

9. Chip removal system: Independent water tank, rear automatic chip conveyor. (Option)

Main technical parameters of machine tool

| Processing capacity | |

| Chuck size | 8inch |

| Maximum Spin Diameter | Ф 500 ㎜ |

| Standard turning diameter | Ф 260 ㎜ |

| Max turning diameter | Ф 360 ㎜ |

| standard turning length | 325 ㎜ |

| Headstock | |

| Spindle speed range | 50r/min-4000r/min. |

| Spindle end Model | A2-6 |

| Main motor power (rated/continuous) | 11/15Kw |

| Torque (rated/continuous) | 127Nm |

| Dimension of front shaft diameter of main shaft | Ф 110 ㎜ |

| Spindle through aperture | Ф 80 ㎜ |

| Bar diameter | Ф 51 ㎜ |

| Tailstock (option) | |

| Maximum stroke of tailstock sleeve | 90 |

| Diameter of tailstock sleeve | F75 |

| Tailstock sleeve taper | 4# |

| feed axis | |

| Travel X direction | 200 ㎜ |

| Travel Z direction | 385 ㎜ |

| Fast forward speed X direction | 20m/min |

| Fast forward speed Z direction | 24m/min |

| Knife Tower | |

| Drive mode | hydraulic servo |

| Number of work | Standard: 8 // 12 bits |

| Single station indexing time | 0.2 seconds |

| Cutter size square cutter bar | □ 25mm |

| Tool size Boring bar | F32 ㎜/F20 ㎜/F16 ㎜ |

| Number of boring tool holders | 4 |

| Number of end face holder | 1 |

| Overall dimensions of machine tool (length×width×height) | |

| Dimensions | 1750mm × 1750mm × 1730mm |

| net weight of machine tool | |

| net weight of machine tool | 3000kg |

Key words:

Related Products

Welcome your message consultation